非開挖式渠道內壁修復 (Pipe Rehabilitation – CIPP Lining)

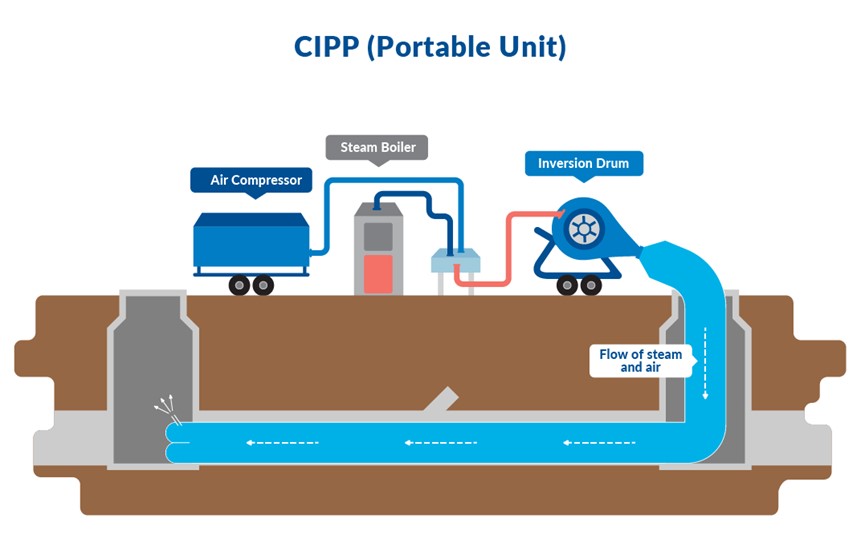

非開挖式渠道內壁修復 (Cured-In-Pipe-Placed Lining)其主要目的是不須在挖掘的情況下修補受損壞的渠筒,大大減低工程對公眾和行車人士的影響,亦可減少工程和機械長時間工作發出的噪音。 另一好處是完成渠道內壁修復後比更換新渠筒的耐用程度提高200%,而去水速度加快了20%以上。 工序方面會使用修補渠道物料安裝在渠道內壁,用蒸氣爐加熱和空氣壓縮機加氣壓令物料充氣擴張固定在筒內,筒內蒸氣溫度需要加熱溫至80度,時間約30分鐘至2小時修補渠道物料才會固化。當然固化的持續時間又取決於管道的長度、直徑、天氣和現場環境。Liner需要冷卻(一般為40度)後,合資格人員在固化管道的末端和頭位使用手工具切割突出來的物料後,整個工程才算完成。

Cured-In-Placed Lining – the main purpose is to repair damaged drainage pipe without excavation work, greatly reduce the impact of the project on the public and motorists, it can also reduce the noise generated by long hours of work and machinery. Another advantage is that the durability of the CIPP lining is improved over 200% than after replacing of the new drainage pipe and the water speed is faster more than 20%. In the process, the repairing CIPP lining material is installed on the inner wall of the drainage pipe, and the steam boiler is heated and the air compressor is filled with air pressure to make the material inflated and fixed in the drainage pipe. The temperature of the steam in the cylinder needs to be heated to 80 degrees, and the time is about 30 minutes to 2 hours. The repair material will only solidify. Of course, the duration of curing depends on the length of the pipe, the diameter, the weather and the on-site environment. After Liner needs cooling (typically 40 degrees), the entire project is completed after the qualified personnel cut the protruding material with the hand tool at the end and head position of the curing pipe.

| 安裝較大型的修補渠道物料 Installation of bigger liner material |

安裝完成 Liner installation is completed |

用蒸氣爐加熱使修補渠道物料固化 Use steam boiler is filled heated to make the liner material solidify |

|

|

|

| 安裝較小型的修補渠道物料 Installation of smaller liner material |

安裝完成 Liner installation is completed |

|

|

修補渠筒內壁使用蒸氣方法圖示